CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

71

Storage capacity

The basin should be able to store the settled particles for some

time unless it is designed for continuous flushing. Continuous

flushing mechanisms are however not incorporated in micro-

hydro schemes due to the complexity of the design and the

scarcity of water during the low flow season. Hence, the storage

capacity must be sufficiently large that the basin does not

require frequent flushing.

Flushing capacity

The basin should be able to be operated so as to remove the

stored particles from it. This is done by opening gates or valves

and flushing the sediment along with the incoming flow in the

basin. The bed gradient must be steep enough to create velocities

capable of removing all the sediment during flushing.

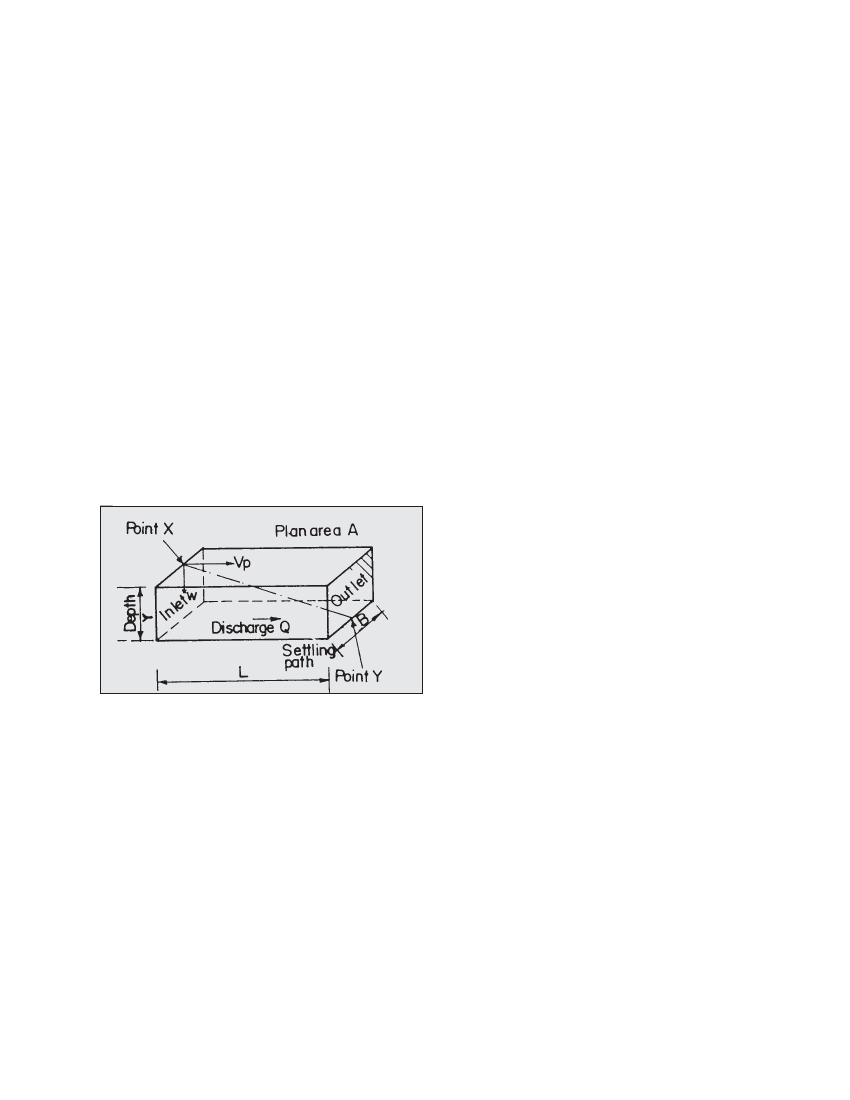

5.3.2 THE IDEAL SETTLING BASIN

The theory behind the design of a settling basin is derived on

the basis of an ideal basin. Therefore, before proceeding to

the design phase, the concept of the ideal basin needs to be

under-stood. Such an ideal basin is shown in Figure 5.1.

Consider a particle entering the “ideal settling basin” on the

water surface at point X (i.e. beginning of the settling zone)

as shown in Figure 5.1. In this figure:

Figure 5.1 An ideal settling basin

L = length of the settling zone (m)

B = width of the settling zone (m)

Y = mean water depth in the settling zone (m),

aslo called hydraulic depth

t = time for particle to travel the length L (s)

Vp = horizontal velocity component of the particle

(m/s)

W = vertical velocity component of the particle

(ms), i.e., “fall velocity” which is discussed

later

Q = discharge (m3/s)

Then the following equations must hold for the particle to

reach the end of the settling basin (point Y):

y = w t (a)

L = vpt (b)

Q = Bvpy(c)

Substituting for y, vpand t from (a) and (b) into (c) results in:

Q = BLw

Therefore, for a given discharge Q, the plan area of the settling

basin can theoretically be determined for sedimentation of a

particle with fall velocity w. However, in practice, a larger

basin area is required because of the following factors:

the turbulence of the water in the basin;

imperfect flow distribution at the entrance; and

the need to converge (sometimes curve) the flow towards

the exit. Therefore in “real basins” the through velocity is

limited, to reduce turbulence, and the required plan area is

about twice the area calculated for the “ideal basin”.

5.3.3 FALL VELOCITY OF SEDIMENT AND PARTICLE SIZE

The fall velocity, w, characterises the ability of particles of

various sizes to settle out under gravity. For a discrete particle,

this value depends on its size, density, and shape, as well as

the temperature of water.

Figure 5.2 shows the fall velocity in water, w, as a function of

the particle diameter for reference quartz spheres. This figure

can be used to estimate w for the calculations required in the

design of the basin. Note that the temperature effect becomes

less for larger diameter particles.

In micro-hydropower schemes, the settling basin is designed

to trap 100% of particles greater than a certain size,

dlimit Only a proportion of smaller particles will be trapped, but

dlimit is set so that the smaller particles passing though the

basin will not cause significant abrasion damage to the turbine.

For micro-hydro schemes the following procedure is

recommended for the selection of dlimit :

Low head schemes, h≤10 m: dlimit = 0.2 mm to 0.5 mm

Medium head schemes, 10 m < h≤100 m : dlimit = 0.2 to

0.3 mm

High head schemes, h > 100 m : dlimit = 0.1 to 0.2 mm

where h is the gross head.

The current practice in Nepal is to use dlimit of 0.3 mm regardless of

the head of the scheme, which is somewhat arbitrary. The approach

outlined in this section is more logical. This is because for a given

particle size, the higher the head, the more the damage is to the

turbine.

The dlimit range given above as a function of head and flow allows the

designer some flexibility in deciding the particle size to be settled.

The following factors should be used while deciding on the

value of dlimit:

If most particles are highly abrasive (quartz sand or minerals),

then the lower limiting values should be used. If the particles

are softer less abrasive substances, then the higher limiting

values may be acceptable.

Crossflow turbines are relatively less sensitive to soft

impurities such as silt and clays. Other types such as the

Francis turbines are more sensitive to any kind of suspended

matter. Pelton turbines are intermediate.